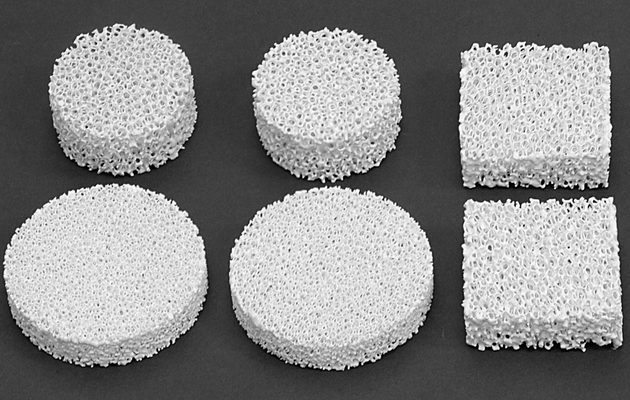

How Did Ceramic Foam Filter Transformed Casting Production?

Quite a long time ago, metallurgists suffered various problems due to poor filtration of molten metals. Of course, it hit the productivity, quality and efficiency in different aspects of casting production. But, the scenario changed significantly after ceramic filtration technology came to the fore. Not only it changed production failures into successes, it provided the satisfaction to customers they were looking for.

It is known that ceramic foam filter has several applications, whether in aerospace industry or foundry industry.

What exactly the Zirconia ceramic foam filter does?

As one imagines about a filter, it flashes in the mind about the filtration procedure for removing the impurities in the molten metal. However, in the past, it wasn’t as qualitative as it was expected. Statistically, the production rate improved after using the Zirconia filter and it yields beneficial results for the industry.

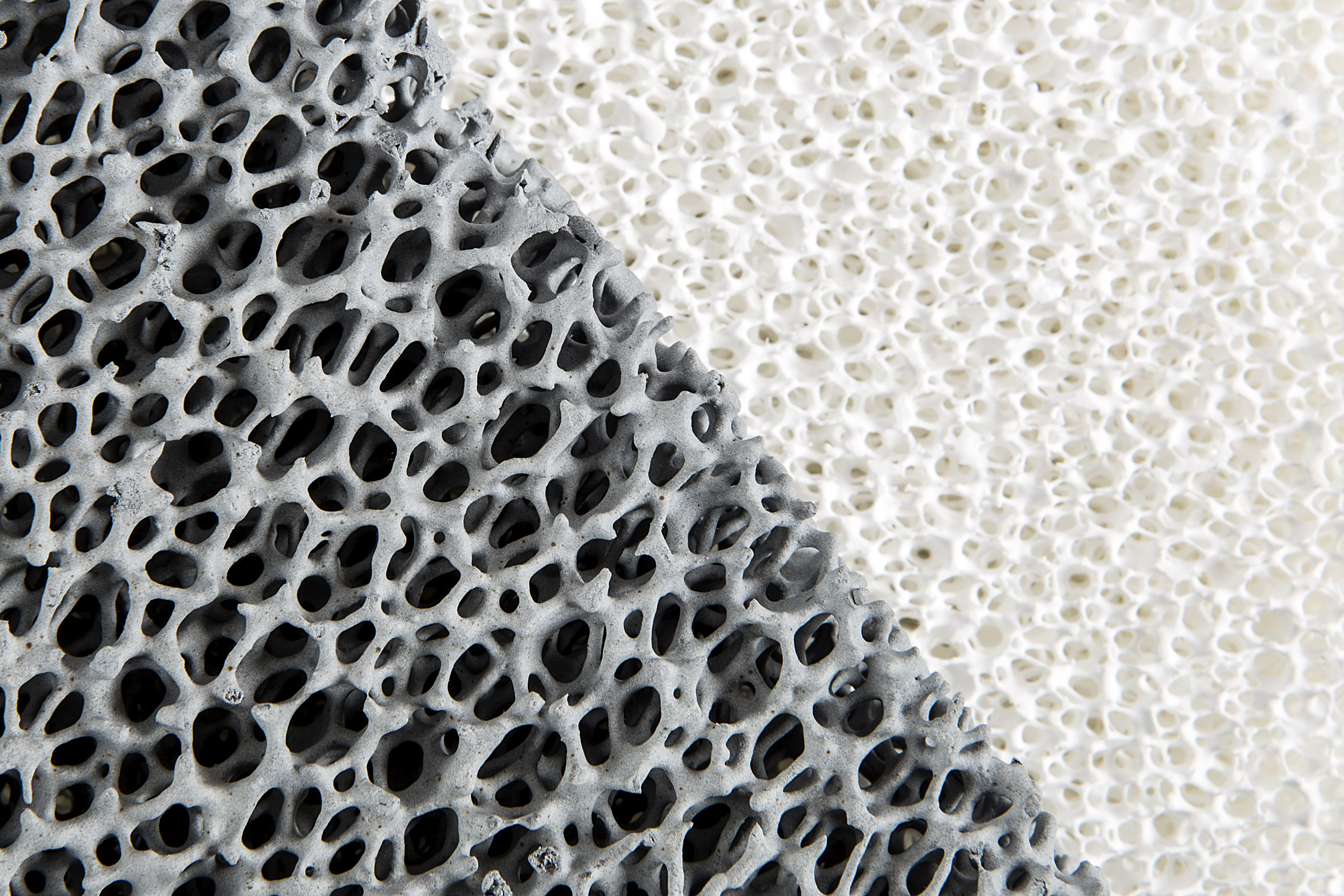

Gas porosity was one of the major reasons that the end product was not uniform in nature. Nevertheless, the foam filters controlled the flow of molten metal and removed gas bubbles in them. Specifically, the honeycomb design of these filters has helped achieve quality filtration. As a result, the scrap and rejection rate have reduced phenomenally.

When observed for quality and consistency, the castings fared with optimal results and reduced the expensive and time-consuming tests. As a whole, the productivity levels shot a new high with higher yields. That’s a remarkable feat that foundry industries have achieved due to an impeccable foam filter technology.

Source: Filter Corp Blog